Well established in some industries, still not used in a lot of others

The numerical simulation of physical processes is already established in many large, technology-oriented companies. In the automotive industry in particular, simulation has become a basic tool. What does this method offer as an advantage over conventional development methods without simulation?

Well-founded decisions – already in the conception phase

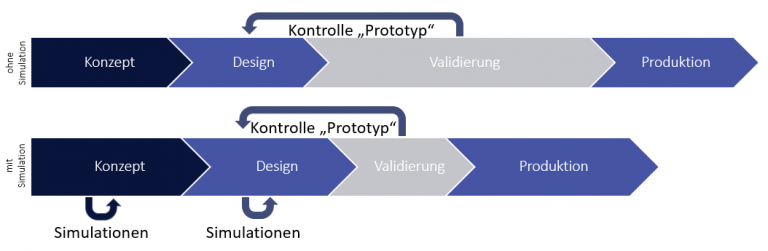

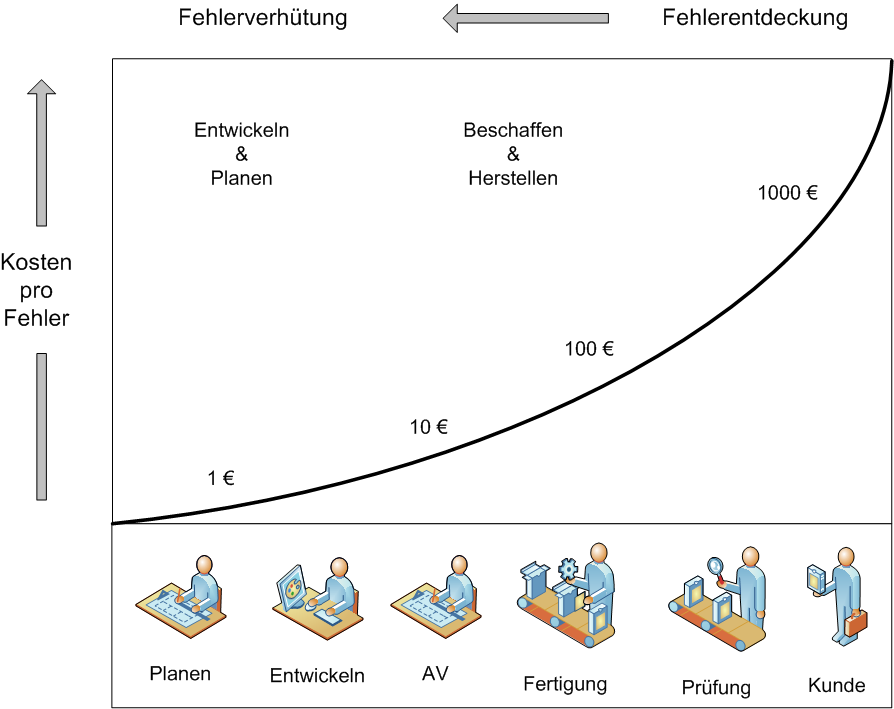

In short, the simulation is a tool in the innovation or development process, which helps to decide on designs or concepts before the first prototype has to be built.

Simulation methods add more control loops to the development process and increase safety in getting a valid design. The development focus shifts more to the conception and design phase. As a result, there are fewer unforeseen errors in the last phases, which are usually more time-consuming and costly.

Fast & optimized solutions – well informed design decisions

Once a physical model has been created, parameter studies can be used to quickly scan a large solution space for ideal solutions. How fast this actually happens depends on the computing time of the model (DOF = degrees of freedom, non-linearities, possibly time dependencies, etc.). In any case, this means an immense time advantage compared to production and real laboratory tests. Expressed terms of mathematical optimization, the higher numbers of design variables and iterations usually result in a significantly better (local) design optimum.

Understanding the physics behind your design challenges will boost your innovation

Another benefit of inspecting the physics in your design is that you will understand your design challenges and limits even better than before. The entire component can be analyzed in order to identify the type and locations of possible critical aspects. For example, thermal bridges, mechanically critical points and, in the case of electromagnetic components, eddy currents or parasitic effects can be quickly identified. This increases the existing physical understanding of the products and processes and leads to new design ideas.

Increase quality, innovation and speed while minimizing risk

In summary, FEA simulation is a tool that can increase the quality and innovation of your development processes and minimize risk. Take advantage of this and get a head start in development through physical simulations!

SSC can help you getting started

If you want to start as quickly and effectively as possible, do not hesitate to contact me for experienced guidance in setting up your FE models.